Fig.1: My logs ready to be sawed at the Hanna Family traditional sawmill located in Lakelands, Cumberland County north of Parrsboro, N.S. Originally a portable sawmill this site became its permanent home in 1940. The photograph was taken in the mid 1980’s and in the 1980’s, the owners ran the mill for only a few days each summer where they only sawed logs for their own use. The logs are on a skidway that joins the so-called log deck located just inside the mill entrance. This arrangement allows logs to be rolled up the skidway and onto the log deck.

Introduction

The Wagstaff & Hatfield shipyard-sawmill at Post Greville, Nova Scotia was one of several traditional, steam-driven sawmills still operating on the Parrsboro Shore during my youth. I am including in this description the Hanna Mill which was located inland at Lakelands, about 20 miles from Port Griville.

The economy of this region was timber-based since logs and lumber were used in sawmills and shipyards. This natural resource based economy had been in existence, in one form or another, since the first settlers arrived in the area. However, the economic prosperity of this region was disappearing quickly when I was growing up in Parrsboro, Nova Scotia.

My family was involved in several diverse aspects of the timber economy. I also participated by helping my father (1894 – 1979) during the summer months and on weekends during the winter. From my memory of this work experience, I will focus on an important component in sawmills called the log carriage. This mechanical device had a direct bearing on father’s business.

In both the steam-driven and the water-powered sawmills, the saw was maintained in a fixed position and the log to be sawed was moved through the saw by placing it on a carriage that ran on long straight tracks. Two basic requirements had to be met for this arrangement to function. The carriage had to be able to support the longest log that the mill might ever need to saw and the track, on which the carriage traveled, had to be more than twice the length of the longest log to be sawed. Logs for sawmills designed for producing market lumber were usually less than 25 feet in length (Fig.1).

This was not the case, however, for sawmills supplying shipyards. These mills had to be able to saw a log that was the full length of a tree (Fig.2).

Fig.2: My father’s construction business involved moving houses. To do this, long timbers “squared” on two sides to form a flat top and bottom surface were placed under the building to be raised and then the building was moved. View More about Moving Houses

The Sawmill Log Carriage

Figures 3, 4 and 5 show the carriage at the Hanna mill. Note that the carriage is long but not nearly as long as the log on the truck in Fig.2. Furthermore, the track for the Hanna carriage does not run outside of the mill as it does as shown in Figures 6, 7 and 8 for the Wagstaff & Hatfield shipyard-sawmill at Post Greville, Nova Scotia.

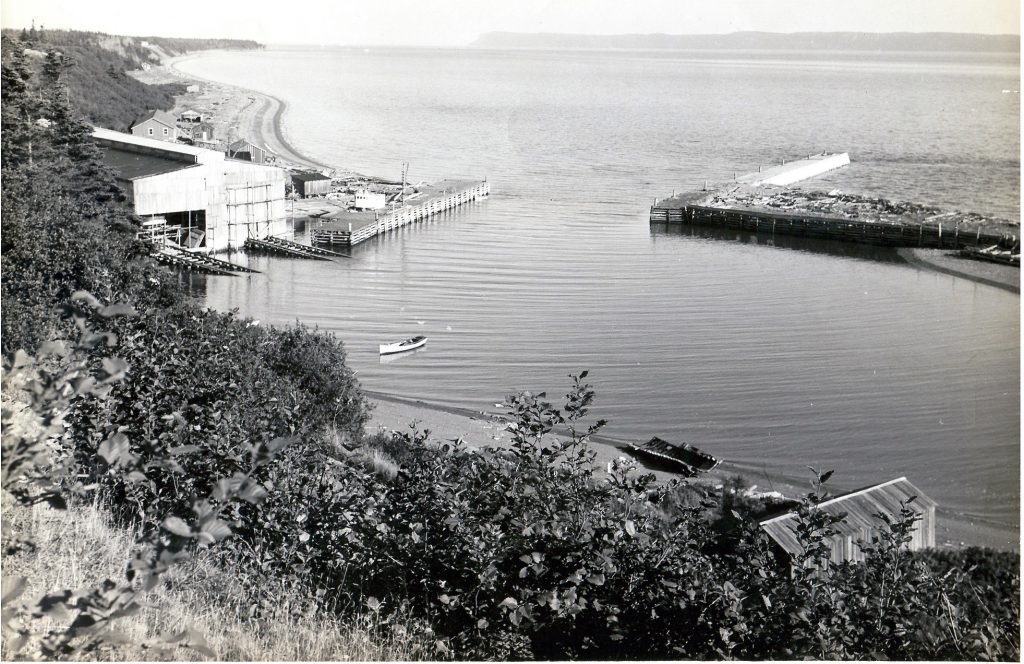

Fig. 3: Log carriage at its start position. This is the location in the mill where a log from the log deck is rolled onto the carriage’s transverse beams. After placing the log on the transverse beams a handle is pulled that causes a ratchet device to turn three pinion gears, each under its own rack on the carriage’s movable structure (see Fig.4 and 5). When the face of this structure is against the log, holding dogs are clamped to the log to hold it in place. These two operations are done in such a way that the log can be passed through the head saw along a line that is parallel to the face of the saw.

If you examine the Wagstaff & Hatfield shipyard-sawmill in Fig.6 (below), you will be able to see that the logs were the complete length of a tree. To add this capacity to the mill, the carriage track was extended well beyond the end of the mill. Also, the carriage may have been longer than the Hanna carriage. As a teenager, I never thought to ask that question and, unfortunately, I did not photograph the Wagstaff & Hatfield shipyard-sawmill, which no longer exists.

Fig. 6: The Wagstaff & Hatfield shipyard sawmill in the 1930,s. Note the length of the logs waiting to be sawed. The band saw in the background is probably powered by a make and break gasoline engine.

The Wagstaff & Hatfield mill could easily, but not necessarily cheaply, “square” my father’s timbers. By sawing one slab off the opposite sides, this mill established a flat top surface and a flat bottom surface making the timber ready to be placed under a building.

When a new timber had to be made quickly, our tree-length logs were taken to the Wagstaff & Hatfield mill. When there was time, my father used a broadaxe to square the timbers by hand. Once again, I wish I had taken photographs of this procedure. Fortunately, a friend gave me two images (Figures 7 and 8) taken in 1973 and James Robarts, a relative, was able to give me a photograph (Fig. 9) of his grandfather and another man using a broadaxe.

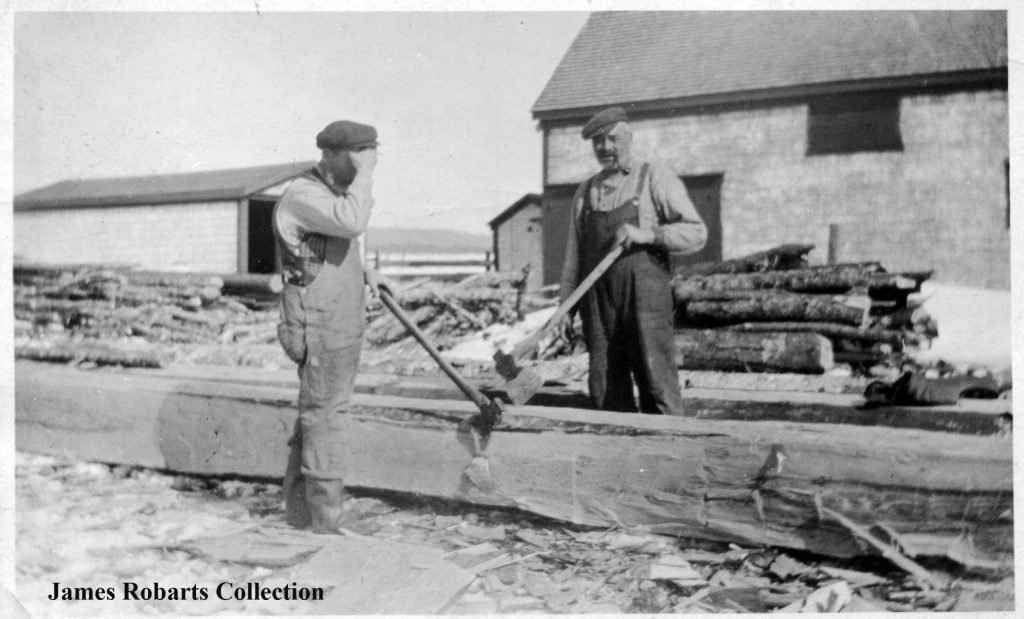

Fig 9. James Edward Morris with the pipe and another, unknown man at Advocate, Nova Scotia. The date is unknown and judging by the size of the stick (an alternate name for a timber) it is possible that the men have started the process of making a mast.

The End of the Wagstaff & Hatfield Shipyard

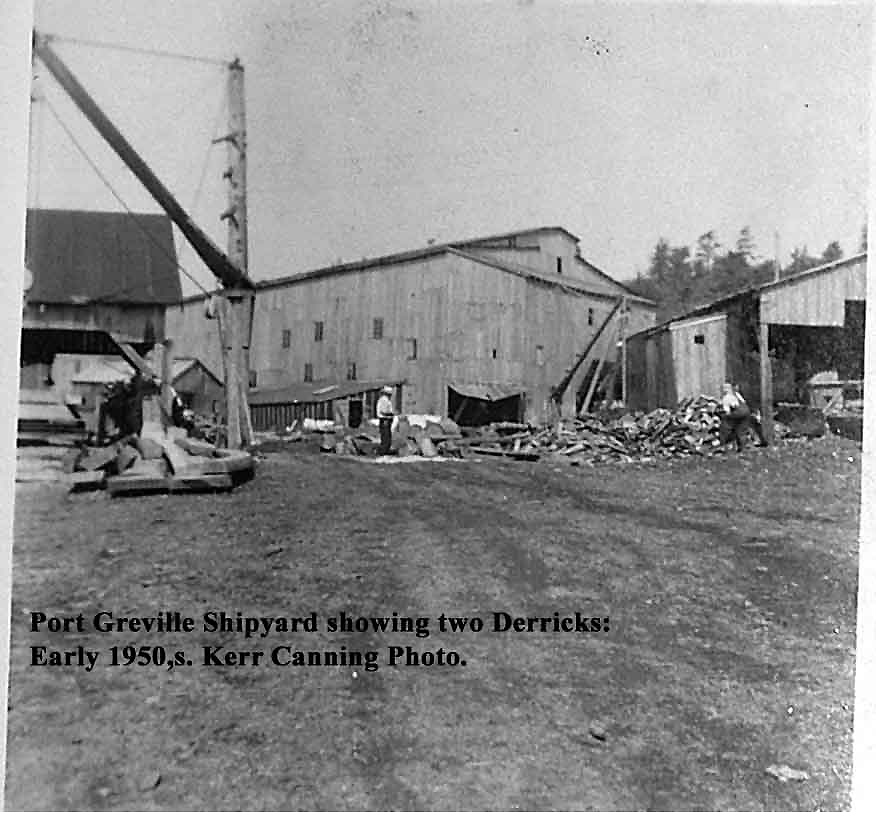

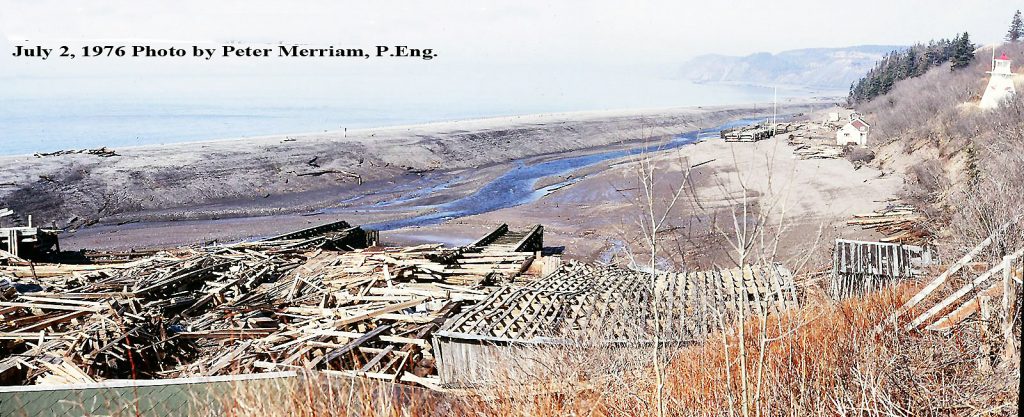

The Wagstaff & Hatfield Shipyard closed in 1972 and four years later many of the major yard buildings were destroyed by the Groundhog Day Gale of 1976. The following photographs show the so called “Big Shed” where the vessels were built. The last photograph is a display of the destruction of this grand old building by a severe winter storm.

Fig 10. Photograph: Keith L. Graham, Fellow of the Architectural Institute of Canada. A WW2 photographs of the Wagstaff & Hatfield Shipyard at Port Greville, N.S. Minesweepers were built in the large two bay shed known as the “Big Shed” and derrick stands on the wharf to the right of the Big Shed. This wharf was called the “Shearwater Wharf”. On the extreme right side of the image is the breakwater wharf.

Fig 11: The Launch of Minesweeper number 1063 in 1942: As with all of the Minesweepers built at the Wagstaff & Hatfield Shipyard, Minesweeper # 1063 was constructed with wood rather than steel. The reason for not using steel is very interesting…Read more under Minesweepers

Fig.12: The Wagstaff & Hatfield Shipyard after WW 2. Thanks to the creation of the The Fishermen loan Board the yard the continued operating until the early 1970. View More about The Fisheries Loan Board

Fig. 13: The remains of the “Big Shed” after it was destroyed by the Groundhog Day Gale of 1976.Read more about the Groundhog Day Gale of 1976.

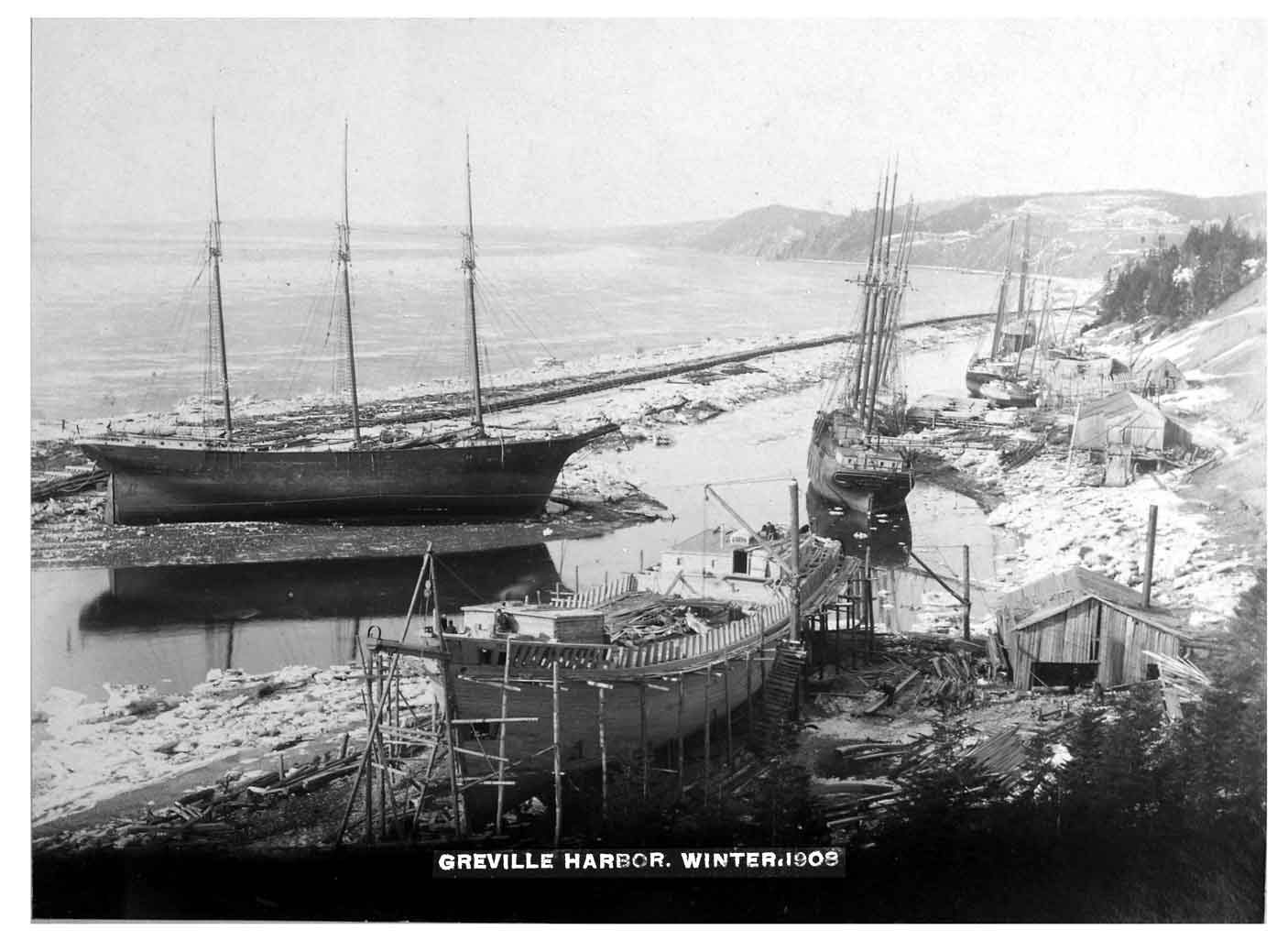

Port Greville Harbour on a winter day in 1908. The three-masted schooner laid up on the gravel bar on the left is the Dara C. The schooner under construction is the T. K. Bently.

A Sainer, built at the Wagstaff and Hatfield shipyard, probably returning from its trial run. Date unknown.

——-

This page developed out of an article I prepared for my friend Sam Manning. He passed away on July 9, 2019. See

A Camden tribute to Sam Manning quietly grows in a special green dory.

The article was titled The Sawmill at the Wagstaff & Hatfield Shipyard in Port Greville, Nova Scotia, Canada.