| NOVA SCOTIA SHIP-BUILDING.BY JOHN R. SPEARS.

For many years past, say for eighty-two at least, the seafaring man has been told that the time was soon coming when sailing ships would be no more. The shapely hull, the towering spars, the snowy canvas – worse yet, the picturesque old marline-spike sailor – were all to be driven from the sea by those ugly but serviceable black tramps, the cargo steam-ships. Few, if any, have been found to deny the assertion, and it followed as a matter of course that if the sailing ship should pass away, the day of the wooden ship was done as well, for, except in special trades, wooden steam-ships have already been superseded. And yet if any one will take a walk along the water-front of any of the Atlantic coast cities, and notably that of the metropolis, he will see more wooden sailing vessels than of any other kind, while could a man have counted the sloops and schooners afloat on the Hudson on the night of the 7th of August last, he would have found many more, I doubt not, than were there on the night of August 7, 1807, when Fulton’s fiery monster sent so many wicked and superstitious sailors to their knees to implore the protection of a kind Father.

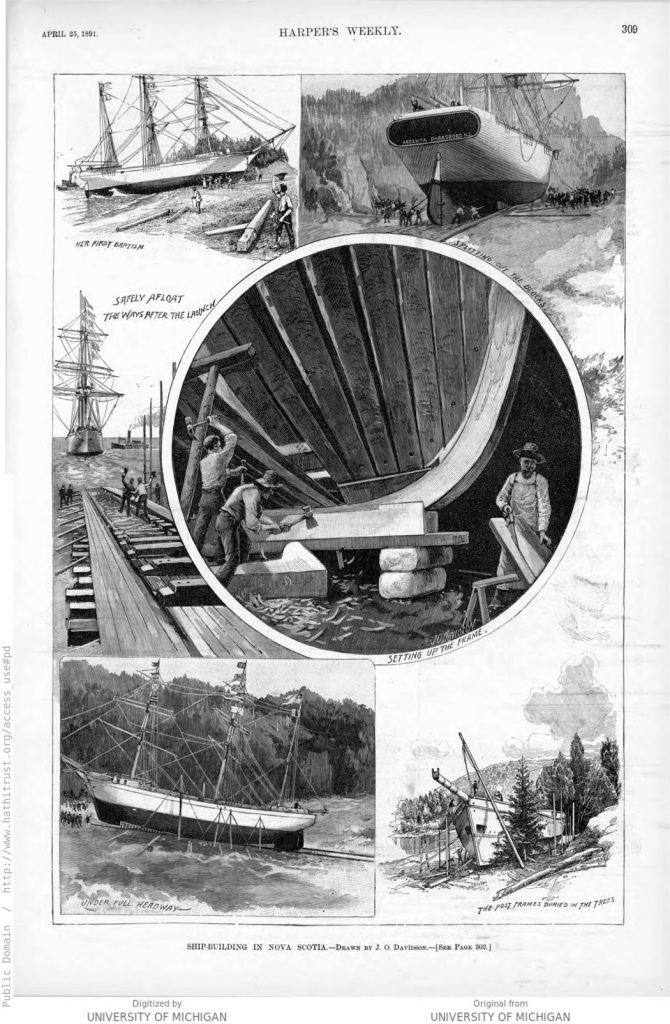

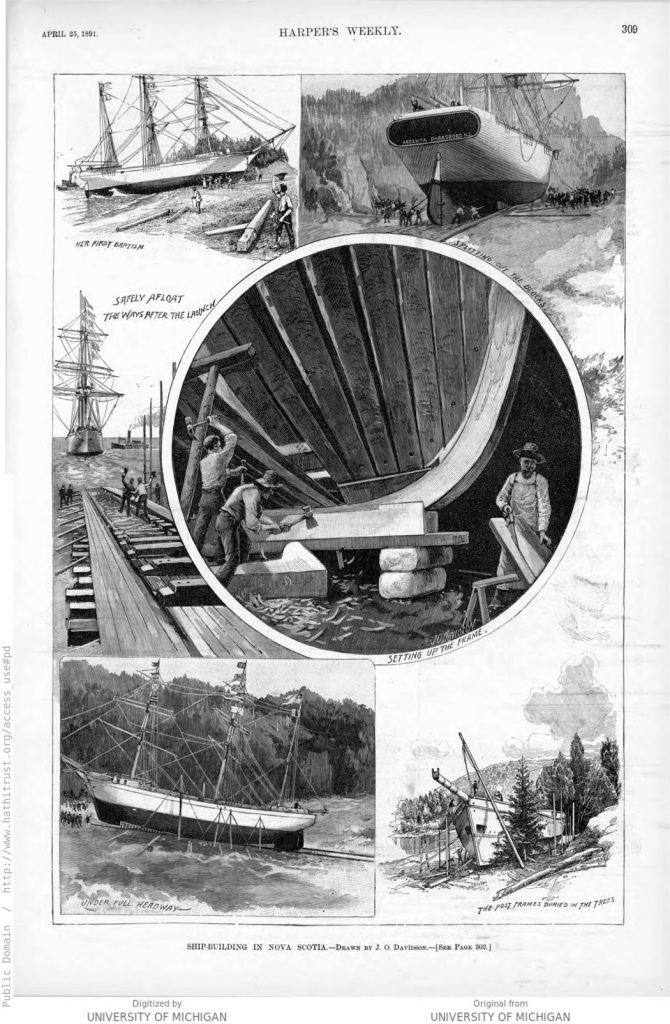

However much of sentiment there may be in the question of ships as discussed by the artist, the storyteller, or the legislator, ships will be built in this port or that, of this form or that, of one material or another, solely as the needle whose loadstone is cash profit points to this or that, the one or the other. It would, I think, have taken but a brief sojourn about the waters of the Bay of Fundy during the season of 1890 to convince anyone that, no matter how serviceable cargo steamers may be, very many ship merchants still find the profit they seek in the wooden walls and bellying sails of the old-fashioned cargo carriers. It was the busiest season known in that locality for perhaps ten years. As illustrating what is there called a busy season, it may be said that between the villages of Parrsborough and Apple River no less than eighteen vessels were on the stocks, their sizes varying from the 80-ton coaster to the mammoth square-rigged deep-watership capable of carrying from 2500 to 3000 tons dead weight. However much of sentiment there may be in the question of ships as discussed by the artist, the storyteller, or the legislator, ships will be built in this port or that, of this form or that, of one material or another, solely as the needle whose loadstone is cash profit points to this or that, the one or the other. It would, I think, have taken but a brief sojourn about the waters of the Bay of Fundy during the season of 1890 to convince anyone that, no matter how serviceable cargo steamers may be, very many ship merchants still find the profit they seek in the wooden walls and bellying sails of the old-fashioned cargo carriers. It was the busiest season known in that locality for perhaps ten years. As illustrating what is there called a busy season, it may be said that between the villages of Parrsborough and Apple River no less than eighteen vessels were on the stocks, their sizes varying from the 80-ton coaster to the mammoth square-rigged deep-watership capable of carrying from 2500 to 3000 tons dead weight.

The building of a wooden ship is not a very difficult problem in mechanics. As done in Nova Scotia it is really a simple matter, for in many yards the primitive methods employed at Boston and Gloucester and other New England ports two hundred years ago still prevail. The broad axe, the handsaw, the adze, the auger, and the maul are still about the only tools used in shaping tree trunks into substantial ship hulls, although few, if any, fail to take advantage of the steam saw-mill in cutting out such parts as the planks and ceiling.

How the ship-owner makes a model representing the half of the hull of the proposed ship; how lines are drawn on this model representing each frame of the ship; how these lines are transferred to paper; and how the lines on paper are transferred to the smoothly planed floor of the second story of the storehouse in the ship-yard, and there enlarged to the full size of the frames to be used in the ship need not be told, for the art is fully described in many works on naval architecture, but that work is the first done in building a ship in Nova Scotia, as elsewhere.

While a tidy draughtsman is thus engaged, the owner of the ship-yard will very likely be tramping over the Cobequid Mountains on snow-shoes; for while ships are built at all seasons, more are laid down in winter than at any other time. He carries an axe on his shoulder, and is accompanied by his boss woodsman, a man who usually knows every tree within twenty miles round about as an ordinary man knows the faces of his friends. The stories of how these men, while marking trees for use in the future ship, see traces of moose and bear and mink and marten – see the animals themselves – and even the “lucifer devil,” would fill a sportsman at once with delight and unrest. Tiresome as snow-shoe tramping is as work for the uninterested, as recreation for one who loves the woods, few outings equal a walk through the forest with a boss woodsman in his search for “natural crooks” and other pieces of timber that will fit the form of a new ship.

Following the boss came the men with axes and ox teams to fell and trim the trees and drag the logs to the mill or the yard, according as they are to be shaped by the hand or the steam saw. At first acquaintance little or nothing would be noticed about these men to distinguish them from lumbermen in the Adirondacks or Michigan. But after a while the experienced sojourner among them would only have to shut his eyes to imagine himself at sea, with the watch at the pump, for they will be found dragging the crosscut-saw to and fro or swaying on a rope or chain to the rhythm of some old shanty chorus like ”Hooray, Sante Anna,” or “Away, Rio.” Scarce a man of them all but has made a deep-water voyage, and many can pass a weather earring or steer a ship as skillfully as they swing an axe or guide a yoke of oxen.

In some yards – at Eatonville is an instance – many timbers are driven down mountain brooks by the aid of picturesque splash dams – dams in which, when water and logs enough are accumulated, a gate may be opened to let the logs float out with a roaring flood. Some, too, are hauled to the yard on tramways, which, as they wind about among the black thickets or cross the blacker waters of a brook, are scarcely less picturesque than the splash dams. Queer places, as it seems to the unaccustomed, are chosen for ship yards. Down at Brookville a great schooner was built where her port-side frames had to be poked up among the trees, that grew almost to the water’s edge, in the narrow little plateau between two hills where her keel was laid. At Canningville another was built on the barren beach, with not even a house in sight. At Advocate, two years ago, one was launched right across the public highway. At Eatonville a bark and a schooner were launched from a sand-bar between two forest-covered mountains, where the nearest dwelling was two and a half miles away up the valley of a mountain brook, and the nearest settlement where a store could be found was at Advocate, ten and a half miles away over the mountains.

The location, however, is of little consequence to the builder so long as he has room for the frames, and space in which to swing a maul, besides. He does not always insist on having even enough water to float his ship when she is launched, for two vessels have been sent flying down the ways at Advocate to land at last in the mud.

A straight path, however, he must have, and in it he places a row of blocks, most carefully lined, with their upper surfaces at such an angle with the water that when the ways are put under the ship, she will slide down them of her own weight. It is on these blocks that the lowest piece of wood in a ship – the shoe – is placed; the shoe being a line of thick planks bolted to the bottom of the keel, which, when the shoe is in place, is at once stretched along on top. The shoe adds little to the strength of a ship, but often saves her by its frailty, for should she settle on a rock with an ebbing tide, the shoe would very likely carry away, and let the ship slide off into deep water.

How large the logs of which the keel and other frames are made must be is determined by certain rules developed by long experience, but nothing further need be said here about that save that when a ship is built for sale on speculation the timbers are always large enough to secure the approval of the inspector appointed by the insurance companies, while the vessel that is built to the order of an owner who expects to keep her – when “she is built to wear out” – the timbers are commonly larger than the rules demand.

The reader has doubtless heard it said many times that the frames of a ship are fitted to the keel like the ribs of a fish to its backbone. That is a very good simile as far as it goes, and if fish only swam with the backbone down instead of up, one could hardly find its equal. But if one would see just how the frames, including that most important one, the stem, are really fitted to the keel, he can learn by looking at the accompanying engraving, which shows the starboard bow frames of a schooner built at Eatonville. The ordinary frames are simply placed on top the keel, and then, after shores are set to hold them upright, metal bolts are driven through frames and keel. It is a curious and interesting fact that not a single frame, with all its bolting to the keel, would stand upright in place if left alone. No frame is capable of supporting its own weight; in other words, the popular idea to the contrary not withstanding, the strength of a ship lies chiefly in her planking, flooring, and ceiling – in the horizontal pieces of wood, and not in the vertical. The reader has doubtless heard it said many times that the frames of a ship are fitted to the keel like the ribs of a fish to its backbone. That is a very good simile as far as it goes, and if fish only swam with the backbone down instead of up, one could hardly find its equal. But if one would see just how the frames, including that most important one, the stem, are really fitted to the keel, he can learn by looking at the accompanying engraving, which shows the starboard bow frames of a schooner built at Eatonville. The ordinary frames are simply placed on top the keel, and then, after shores are set to hold them upright, metal bolts are driven through frames and keel. It is a curious and interesting fact that not a single frame, with all its bolting to the keel, would stand upright in place if left alone. No frame is capable of supporting its own weight; in other words, the popular idea to the contrary not withstanding, the strength of a ship lies chiefly in her planking, flooring, and ceiling – in the horizontal pieces of wood, and not in the vertical.

Just how a ship, and a big one at that, looks with all her frames in place, but without the skin or planking, can be seen by an inspection of the illustration of the great square-rigged vessel built at Spencer’s Island.

The picture shows as well how a scaffolding must be erected for the men to work on as the frames are raised. It shows, too, a shed at the left, where the men who are fashioning the timbers may work when the rain falls – on “a dull day,” as they say there – or when the sun “burns the fog away, and comes out scorching hot, ye know.” Further than that, it shows a tall spar used as a derrick in lifting up the timbers into place. If one would get a good idea of how large a great ship is, the picture will help in the matter, for the lower edge of the shed roof was high enough for a tall man with a silk hat on to walk erect under it. The derrick was as tall as the loftiest telegraph pole in New York, and the hull itself would have fill ed Broadway for a block from curb to curb could it have been placed there, while the highest timbers would have been up about the fourth-story windows of the ordinary business houses.

The work of shaping the timbers for the frame of a ship is done with the saw, the axe, and the adze. It is not fine work in the sense that cabinet-work is fine, but anyone who looks at the joints between timbers – the scarfs, as they are called – must be impressed with the skill of the man who can wield such large tools in a way to make the two pieces fit so closely together. The scarf in the schooner’s stem as shown made a scarcely noticeable line in a good photo graph taken under favorable circumstances.

But when the planks and ceiling are to be put on, something else than the use of the tools mentioned is needed. Crooked logs can be found and shaped for crooked or rounding frames, but where the planks and ceiling must be fitted over rounded frame surfaces they are bent until they fit into place. In a well-built ship that will carry 1000 or 1200 tons of cargo the planks are five inches thick and six or eight wide – pretty good timbers rather than plank, a house carpenter would say. But even these can be bent to fit a very sharp curve if they are properly steamed, and a steaming box is therefore to be found in every ship-yard.

Its name is almost sufficiently descriptive, for it is a box long enough to hold the largest plank, and is connected with a great pot having a wooden cover by means of a tin or iron pipe to convey the steam from the boiling pot to the box. The rule is to steam the plank an hour for every inch of thickness. “But they don’t always get it,” as a builder said to me, “because you can generally scream ’em into place, ye know.” One who has heard a partly steamed plank protest as it was forced to its place will say that the word “scream” is graphically descriptive.

Perhaps no part of the work of building a wooden ship is more likely to strike the attention of a stranger (“strike” is a particularly good word, because the novice is usually a little shocked by what he sees) than that of fastening the plank and ceiling to the frames. He sees the men carry the plank, perhaps steaming hot, to the frames, lift it to its place, and then with screw clamps hold it there. Then comes a man with an augur, who bores two holes in the plank to every frame, the holes piercing the frame as well as the plank. There is nothing shocking about that but when one notices that the augur holes are, say, only an inch and an eighth in diameter, and that nothing but wooden pegs are driven in to hold the plank to the frames, that that whole vast frame-work of the ship is apparently held together by such frail fastenings as wooden pegs, he begins to wonder how it happens that the ship does not fall apart before she is launched. However, the fact is not so bad as it appears to be to a novice. To begin with, the frame-work of a ship is secured together by iron bolts, while the ends of plank and ceiling are fastened by iron or brass (composition) bolts that have a head on one end and are riveted off over rings at the other. The fastening may seem frail, but there are good wooden ships afloat that are thirty, forty, and even fifty years old. It will be noted by the novice as a curious fact that in building a 1000-ton ship two and sometimes three sets of augurs will be worn out by their friction with even the soft woods.

After the hull is well along, come the sparmakers and riggers. The blacksmith has been on hand all the time to make bolts, if for no other purpose; but when the spar-maker comes, his work increases rapidly, for in these days iron is used wherever possible in even a wooden ship. There is seemingly no end to the collars, the hooks, the eyes, the slings, what not, that he must make; and at the last, when a 1000-ton ship is nearing completion, from six to nine men will be employed about the forges. Here, too, is a case where the skill of the mechanic shows itself in the use of heavy tools to make fine work, for the fitting done by some of these Nova Scotia blacksmiths looks marvellous in the eyes of the novice. It is all the more noticeable in Nova Scotia from the fact that it is all hand-work, few if any such aids to human muscle as steam trip-hammers, bolt-machines, etc., which are common in Maine ship-yards, can be found there.

The logs on which the spar-maker sets to work are for the most part cut in the woods where the rest of the ship’s wood came from. Now and then the lower masts of a ship are made of Oregon pine, and iron masts are not unknown. The Argenta, a bark built at Eatonville last summer, had an iron bowsprit and jib-boom in one. It was imported from England, was the first of its kind used in Nova Scotia, and was the talk of the maritime provinces. But most of the spars of a Nova Scotia ship are made of Nova Scotia spruce, and, according to Nova Scotia shipbuilders, Nova Scotia spruce is unique. Whether it is the fog, or the prevailing winds, or the soil that makes it they do not know, but Nova Scotia spruce, they say, is the toughest on earth, and in that dictum many New York ship merchants join, for many New York merchants own Nova Scotia ships.

The modern use of wire in the rigging of a ship is enough to make the old-fashioned sailor of the clipper-ship era gasp. That shrouds and stays should be made of wire rope is not much of a subject for wonder, but with the perfection of steel wire is coming the abandoning of manilla and chains in many places where the one or the other must run around a pretty small sheave. A combination of chain and manila has been used time out of mind in the gear for hoisting sails, in the sheets or tackle for stretching the lower corners of square sails to the yards, and in the braces which sway or point the yards this way and that. But now the flexiible steel-rope, tough, enduring, and low priced, is coming into universal use. To themarline-spike, knife, and serving mallet, the chief tools of the rigger in old days, must now be added the nippers.

Last of all come the caulkers, who drive the seams full of oakum, the joiners or house carpenters, who build the cabin and forecastle, and the painters “to hide the defects” and so it happens that one of the busiest looking places in the world is a ship-yard as the vessel is near completion. With the bolt driver setting home the last of the fastenings with his maul, the dubber “squaring down “the sides with his adze, the caulker driving in the oakum, the spar maker chopping away at spare yards and topmast, the rigger whirling his serving mallet or swaying aloft some of her top-hamper, the carpenter nailing up bunks for the crew, the painter spreading the color, and the general-utility man carrying stores on board, there is a clatter and swing and movement that will stir the blood of the most blasÈ.

Nor will a study of the people themselves prove less interesting than the work they are doing. Let one instance serve to illustrate this. I sat one afternoon in the tent on the beach where the master-mechanic at Eatonville lived. His wife, a sweet-faced, gentle voiced matron, was showing the photographs in her album – photographs of relatives or close friends and neighbors in all cases. As she turned the leaves she told the name of each, and then added, so often that it made my heart ache, such comment as this: “He was on the schooner Belle; she was lost with all hands on the coast of Maine.” “He was on the deck of the Queen, when a wave washed him away, and he was lost.” “He was mate of a ship sailing from New York, and in aquarrel with one of the men was stabbed to death.” “He and his wife were caught in the ice, and with all hands perished.” “His ship sailed from St. John one day in spring, and was never heard from again.”

To those who live on the shores of the Bay of Fundy the sea is at once a harvest field and a grave. The great men of the country are the captains and owners of ships; the rising young men are second and first mates the prudent are those who have invested early savings in ship shares; the desolate are those whose hope and comfort in life have sailed away, never to return.

At last, though time is never laggard in a ship-yard, launching day is at hand. Not that the ship is completed; “most generally a fortnight’s work oughter be done first” but the owner is tired of waiting for her, and the builder is willing to see her go. And so the most of the carpenters and laborers are set to work getting the ways in place and building a cradle under her, laying a railway of heavy timbers, down which the ship may slide, and building a frame-work to hold her as she goes. Where the water shoals gradually the ways may be laid on the ground for the entire distance, but inmost places about the Bay of Fundy the shores are steep, and the water end of this railway must be a substantial trestle, well braced and spiked together, and held down at high tide by barrels of gravel from the beach – something that always looks very funny to the novice.

Meantime the builder has gone or sent away to the nearest printing-office to have some posters printed announcing the red paper – green, red, or yellow – and bold type are in high favor for such occasions. Here is the wording of such a bill:

Such an invitation will draw hundreds of spectators. At the launching of the bark Argenta at Eatonville in August, when I was present, I saw people who had driven more than thirty miles in order to see the launching. They all came in holiday attire, old and young, parents and children, lovers and sweethearts – all very gay, and all very much interested in any peculiarities or unique features about the ship, and all watching for signs that will indicate what her luck is to be.

With hundreds of critical and no end of mischievous eyes upon them, the men do the last strokes of work about the ways and the ship with a will and a care that, exercised all along, would have made a better ship in half the time. The spectators swarm everywhere. They stand and sit on the debris alongshore; they gather in the shade of tool-house and shed; they clamber up the staging, and get in the way of the men at work; a few of the young people in couples commonly stray off to out-of-the-way places in the yard in a manner that indicates a greater interest in something other than ship-building. The foreman frets and fumes about on all sides the builder, silent but anxious, watches the doings with his hands in his pockets; the owner, bland and smiling, receives the ladies on the quarter-deck, and compliments them on their charms, while they praise the new ship, and admire the bunting with which – she is always decorated.

Finally the time comes when the tiny waves of the flood-tide break over the tops of the barrels of gravel that hold down the outerways. The water will rise no higher, and a gang of sturdy young fellows with mauls and wedges crawl under the stern end of the ship’s cradle, and begin to split out the blocks on which the weight of the ship rests. There has been no end of chopping and pounding and clatter all along, but the click of maul and wedge is different, and the sound hush es the busy tongues, even stills the wail of the tired baby, for it is a signal that announces the quick departure of the new ship, never to return. Silent, but nervously shift ing about in their places, the spectators gaze at the motionless hulk, while the ”click, click” from under the cradle grows muffled as the men go further in, and louder again as they near the end, until at last the tops of the tall spars are seen to tremble faintly, and then, with slow but quickening speed, she glides away. Sweeping over the bend of the beach, she cuts a shining curl of foam from the crest of the wave that rises to meet her,tips lightly from the end of the cradle, and floats away, bowing in gentle courtesy to the throngs upon the shore.

Click on image for larger version |